Fonderia Zardo is ISO 9001:2015 and ISO 45001:2018 certified and invests the utmost commitment in the quality control process in terms of investment of human, instrumental and economic resources, to pursue responsible development objectives towards all stakeholders.

Quality control is the final stage of casting production. The aim is to verify that all the requirements requested by end customers are achieved.

For all gray cast iron and spheroidal iron castings, a complete material certification is provided, according to the agreements made with the customer.

We use software designed exclusively for the quality department such as ITACA QualityCheck.

This is a software module integrated with the other modules of the ITACA ecosystem (ITACA X, ITACA VISION, ITACA ANALISYS, ITACA PYRO) which is divided into two phases:

1. Analysis of the casting batch

Thanks to the direct connection to ITACA X, ITACA QualityCheck shows operators the production status of the batch they need to analyze. The main screen displays all the alarms relating to that specific casting, suggesting the main types of defects that can affect the production batch.

2. Insertion of quality tests

In addition to displaying the acquired production parameters, it allows the insertion of real results of quality controls such as:

• Mechanical properties

• Visual checks

• Hardness test

• Videos

• Liquid penetrants

• Micrographs

• X-rays

• Ultrasound

QUALITY CONTROL EQUIPMENT:

One WOLPERT HARDOMETER for HB hardness tests

One USM GO+ ultrasound digital for integrity check

One KRAUTKRAMER DSM ultrasound digital thickness measurer

One CIGIEMME magnetic crack detector for fluorescent inspection (with wood lamp)

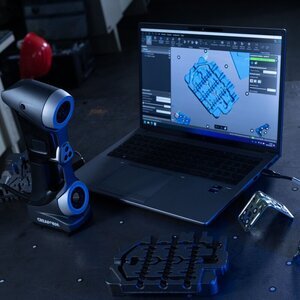

LASER SCANNER 3D Handy Scan 700 elite:

Equipped with Vx Inspect Quality Control software, the portable 3D scanner does not require a tripod or external tracking devices to operate. Provides results in seconds, anywhere. It allows you to precisely and reliably measure parts of any size, material or complexity with: accuracy: 0.025 mm volumetric precision: 0.020 mm + 0.040 mm/m