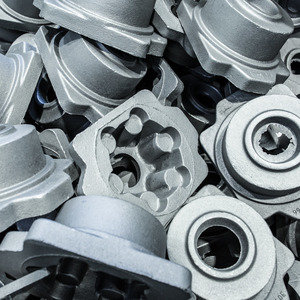

One of the most important aspects for the production of high quality gray and ductile iron castings is the efficiency of the cooling process, determined by the residence time of the castings inside the tunnel.

In Fonderia Zardo all cast iron castings remain in the cooling tunnel for 4 hours

The cooling tunnel is composed of a pneumatic system of air cushion springs for conveying and cooling GENERAL KINEMATICS jets

One DISA CT4 shoot -blasting machine capacity 13T/H

Two OSGM shoot-blasting machine rampant blet and tunnel